Fertilizer granulator machine price

A fertilizer granulator machine plays a crucial role in the production of granular fertilizers, which are easier to handle, store, and apply.

Machine Capacity:

The capacity of a fertilizer granulator machine, measured in tons per hour or kilograms per hour, significantly affects its price. Machines with higher capacities are generally more expensive due to their ability to handle larger quantities of raw materials and produce a greater volume of granulated fertilizer within a given time frame. Consider your production requirements and choose a machine that aligns with your needs.

Granulation Technology:

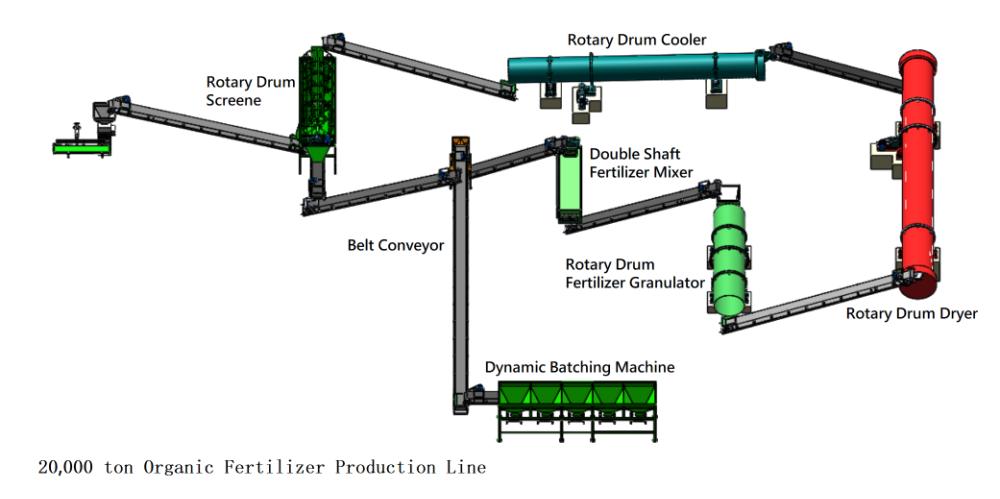

Various granulation technologies are employed in fertilizer granulator machines, including drum granulation, disc granulation, and extrusion granulation, each with its own advantages and price considerations. Drum granulators are generally more cost-effective, while extrusion granulators tend to be more advanced and pricier due to their high production capacity and precise control over granule size and shape.

Machine Size and Design:

The physical size and design complexity of a fertilizer granulator machine also influence its price. Larger machines with more sophisticated designs may come at a higher cost. Consider the available space in your production facility and the specific features you require, such as automated control systems or additional functions like drying or cooling.

Material of Construction:

The quality and durability of the materials used in the construction of the fertilizer granulator machine can impact its price. Machines constructed with high-quality materials, such as stainless steel or corrosion-resistant alloys, tend to be more expensive but offer better longevity and resistance to wear and tear. It is important to strike a balance between quality and cost-effectiveness.

Brand and Reputation:

The brand reputation and market presence of the manufacturer also play a role in determining the price of a fertilizer granulator machine. Established brands with a strong track record and positive customer reviews often command higher prices due to their reputation for reliability, quality, and after-sales support. However, it’s important to research and compare different manufacturers to ensure you’re getting the best value for your investment.

After-Sales Support and Warranty:

Consider the level of after-sales support provided by the manufacturer and the warranty offered for the fertilizer granulator machine. A comprehensive warranty and reliable customer support can add value to your purchase and give you peace of mind knowing that any potential issues will be promptly addressed.

When considering the price of a fertilizer granulator machine, it’s important to evaluate factors such as machine capacity, granulation technology, machine size and design, material of construction, brand reputation, and after-sales support.