Fertilizer granulation

Fertilizer granulation is a crucial process in the production of fertilizers that involves transforming raw materials into granular form. Granular fertilizers offer several advantages, including improved nutrient release, reduced nutrient loss, and convenient application.

Significance of Fertilizer Granulation:

Fertilizer granulation plays a vital role in optimizing nutrient delivery to plants. The process involves combining essential nutrients, binders, and additives to form uniform granules. Granular fertilizers offer several advantages over other forms, such as enhanced nutrient release, reduced leaching, improved handling, and precise application control.

Different Granulation Techniques:

Rotary Drum Granulation:

This technique involves the use of a rotary drum granulator, where raw materials are fed into the rotating drum. As the drum rotates, a liquid binder is sprayed onto the materials, causing them to agglomerate and form granules. The tumbling action of the drum helps create uniformly sized granules.

Pan Granulation:

Pan granulation utilizes a disc or pan granulator, where the raw materials are fed onto a rotating disc. The disc’s high-speed rotation causes the materials to adhere together, forming spherical granules. The addition of a binder or liquid solution aids in the granulation process, resulting in well-formed granules.

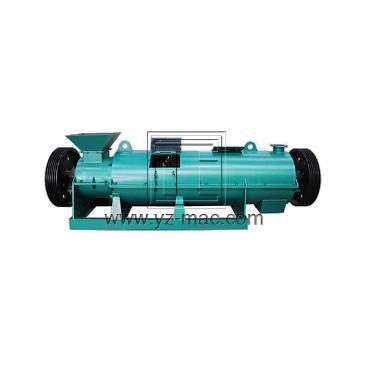

Extrusion Granulation:

Extrusion granulation involves forcing the raw materials through a die under high pressure. The pressure causes the materials to bind together and form cylindrical granules. This technique is commonly used for materials that are difficult to granulate using other methods and allows for precise control of granule size.

Benefits of Granular Fertilizers:

Controlled Nutrient Release: Granular fertilizers are designed to release nutrients gradually over time, providing a steady supply to plants. This controlled-release feature ensures optimal nutrient uptake, minimizes nutrient leaching, and reduces the risk of over-fertilization.

Reduced Nutrient Loss: Granular fertilizers have a lower risk of nutrient loss through leaching or volatilization compared to other forms. The granules’ structure helps retain nutrients within the root zone, allowing plants to efficiently utilize them and minimizing environmental impact.

Improved Handling and Application: Granular fertilizers are easy to handle, store, and transport due to their uniform size and shape. They can be accurately applied using various spreading equipment, ensuring even distribution across the field or garden. This ease of handling and application saves time and labor during fertilizer application.

Customized Formulations: Granular fertilizers offer flexibility in nutrient composition and formulation. Manufacturers can tailor the nutrient ratios based on specific crop requirements, soil conditions, and targeted nutrient deficiencies, providing a customized solution for various agricultural needs.

Enhanced Crop Performance: Granular fertilizers deliver nutrients directly to the root zone, maximizing their availability to plants. The controlled-release nature of granules ensures a consistent nutrient supply, promoting healthy plant growth, improved yield, and overall crop performance.

Fertilizer granulation plays a vital role in optimizing nutrient delivery and maximizing fertilizer efficiency. With various granulation techniques available, such as rotary drum, pan, and extrusion granulation, manufacturers can produce high-quality granular fertilizers. Granular fertilizers offer several advantages, including controlled nutrient release, reduced nutrient loss, improved handling and application, customizable formulations, and enhanced crop performance.