Fertilizer equipment

Fertilizer equipment refers to various types of machinery and equipment used in the production of fertilizers. This can include equipment used in the processes of fermentation, granulation, crushing, mixing, drying, cooling, coating, screening, and conveying.

Fertilizer equipment can be designed for use with a variety of fertilizers, including organic fertilizers, compound fertilizers, and livestock manure fertilizers. Some common examples of fertilizer equipment include:

1.Fermentation equipment: This includes equipment such as compost turners, fermenters, and inoculation machines, which are used to convert organic waste into high-quality organic fertilizer.

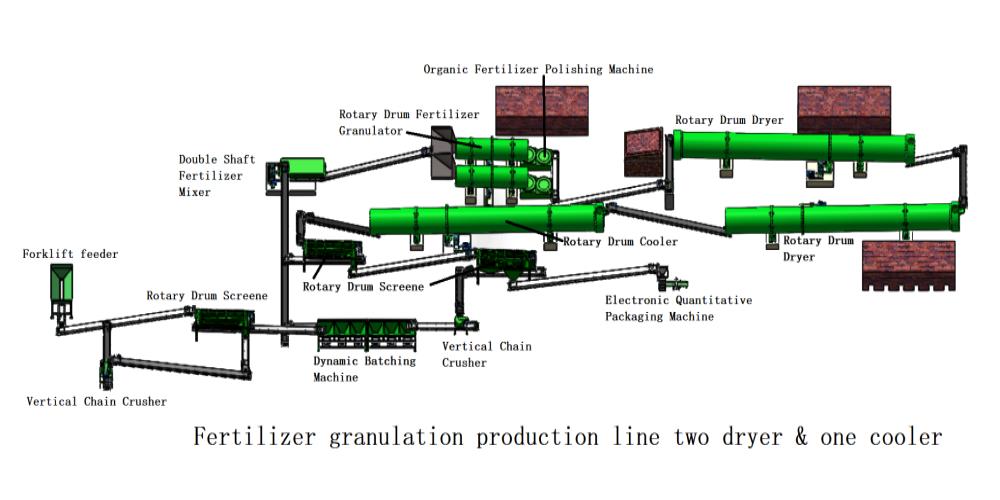

2.Granulation equipment: This includes equipment such as disc granulators, rotary drum granulators, and double roller granulators, which are used to convert raw materials into granular fertilizers.

3.Crushing equipment: This includes equipment such as crushers and shredders, which are used to crush or shred raw materials to facilitate the granulation process.

4.Mixing equipment: This includes equipment such as horizontal mixers, vertical mixers, and single-shaft mixers, which are used to blend different materials together to create fertilizer formulations.

5.Drying and cooling equipment: This includes equipment such as rotary dryers, fluidized bed dryers, and counterflow coolers, which are used to dry and cool the granular fertilizers after they have been formed.

6.Coating equipment: This includes equipment such as rotary coaters and drum coaters, which are used to apply a protective coating to the surface of the granular fertilizers.

7.Screening equipment: This includes equipment such as vibrating screens and rotary screens, which are used to separate the granular fertilizers into different sizes.

8.Conveying equipment: This includes equipment such as belt conveyors, screw conveyors, and bucket elevators, which are used to move the granular fertilizers between different stages of the production process.