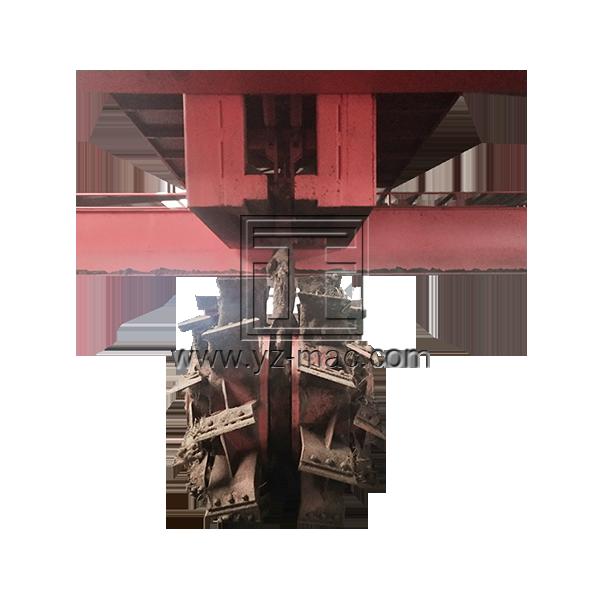

Fertilizer compost machine

Fertilizer blending systems are innovative technologies that allow for precise mixing and formulation of fertilizers. These systems combine different fertilizer components, such as nitrogen, phosphorus, potassium, and micronutrients, to create custom fertilizer blends tailored to specific crop and soil requirements.

Benefits of Fertilizer Blending Systems:

Customized Nutrient Formulation: Fertilizer blending systems offer the flexibility to create custom nutrient blends based on soil nutrient analysis and crop nutrient requirements. This allows farmers and agronomists to tailor fertilizers to meet specific nutrient deficiencies, ensuring optimal plant nutrition and maximizing crop yields.

Precise Nutrient Ratios: Fertilizer blending systems enable precise control over nutrient ratios, ensuring accurate application of nutrients to the soil. This precision minimizes the risk of over-fertilization or under-fertilization, promoting efficient nutrient uptake by plants and reducing nutrient losses to the environment.

Increased Efficiency and Cost-Effectiveness: By blending fertilizers on-site, fertilizer blending systems eliminate the need for pre-packaged fertilizers. This reduces transportation costs, storage requirements, and inventory management. Additionally, it allows for timely adjustments to fertilizer formulations based on changing soil conditions or crop nutrient demands.

Enhanced Product Quality: Fertilizer blending systems ensure consistent and uniform blending of fertilizer components, resulting in high-quality fertilizer products. Homogeneous nutrient distribution within the blend ensures even nutrient availability to plants, promoting balanced growth and reducing the risk of nutrient imbalances.

Working Principles of Fertilizer Blending Systems:

Material Handling: The system receives bulk fertilizer components, such as granules, powders, or liquids, and stores them in separate compartments or silos. Automated conveyors or pneumatic systems transport the materials to the blending area.

Weighing and Metering: The system accurately measures and controls the quantity of each fertilizer component to be blended. This is achieved using precision weighing scales and automated metering devices, ensuring the desired nutrient ratios are achieved.

Blending and Mixing: The measured quantities of fertilizer components are thoroughly mixed using blending mechanisms such as rotary drums, ribbon mixers, or paddle mixers. The blending process ensures a uniform distribution of nutrients throughout the fertilizer blend.

Bagging or Bulk Loading: Once the blending is complete, the blended fertilizer can be packaged into bags of various sizes or loaded directly into bulk storage containers or trucks for distribution.

Applications of Fertilizer Blending Systems:

Agricultural Farming: Fertilizer blending systems are widely used in agricultural farming, providing farmers with the ability to create custom fertilizer blends tailored to specific crop and soil requirements. This ensures optimal nutrient management and supports sustainable agriculture practices.

Commercial Fertilizer Production: Fertilizer blending systems are employed by commercial fertilizer manufacturers to produce a wide range of blended fertilizers. These systems enable manufacturers to efficiently produce custom blends for various crops and market demands.

Soil Remediation and Reclamation: Fertilizer blending systems find applications in soil remediation and land reclamation projects. By precisely formulating nutrient blends, these systems help restore nutrient-depleted soils and improve soil fertility for successful land rehabilitation.

Specialty Crop Production: Fertilizer blending systems are beneficial for specialty crop production, such as horticulture, greenhouse cultivation, and hydroponics. These systems allow growers to formulate specialized nutrient blends that meet the specific nutritional requirements of these crops.

Fertilizer blending systems offer precision, efficiency, and flexibility in fertilizer production. They allow for customized nutrient formulations, precise nutrient ratios, increased efficiency, and enhanced product quality. Fertilizer blending systems find applications in agricultural farming, commercial fertilizer production, soil remediation, and specialty crop production.