Fast delivery China Counterflow Cooler - Rotary Single Cylinder Drying Machine in Fertilizer Processing – YiZheng

Fast delivery China Counterflow Cooler - Rotary Single Cylinder Drying Machine in Fertilizer Processing – YiZheng Detail:

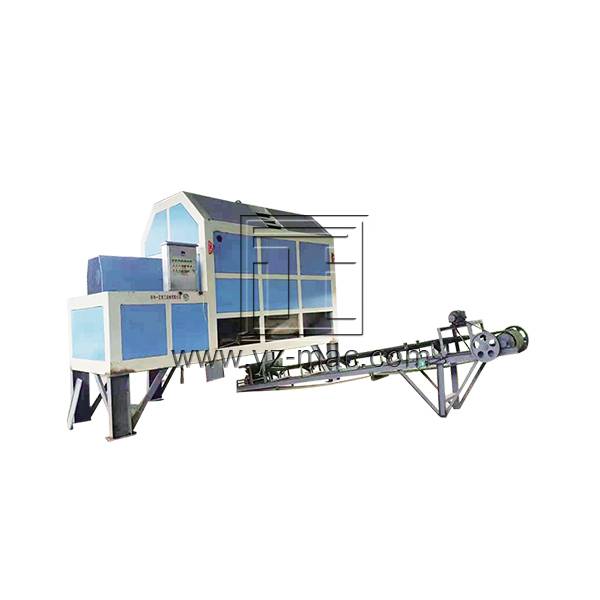

The Rotary Single Cylinder Drying Machine is a large-scale manufacturing machine used to dry shaped fertilizer particles in fertilizer making industry. It is one of the key equipment. The Rotary Single Cylinder Drying Machine is to dry organic fertilizer particles with a water content of 50%~55% after granulation to a water content ≦30% to meet the standard of organic fertilizer. When used for long-term storage or as a raw material for further processing, the moisture content must be ≦13%.

Rotary Single Cylinder Drying Machine is widely used for drying slag limestone, coal powder, slag, clay, etc. The Drying Machine can also be used in building materials, metallurgy, chemical, and cement industry.

Materials are sent to hopper of Rotary Single Cylinder Drying Machine by belt conveyor or bucket elevator. The barrel is installed with slope to horizontal line. Materials enter the barrel from the higher side, and hot air enters the barrel from the lower side, materials and hot air mix together. Materials go to the lower side by gravity when the barrel rotates. Lifters on the inner side of barrel lift materials up and down to make materials and hot air mix completely. So drying efficiency is improved.

* Reasonable structure, excellent fabrication, high production, low consumption, economical and environmental, etc.

* The special internal structure of rotary Drying Machine ensure the wet materials that will not block and stick the Drying Machine.

* Rotary Drying Machine can resist the high temperature so that it can dry the material quickly and have a large capacity.

* Rotary Drying Machine is easy to operate and maintain.

* Rotary Drying Machine can use coal, oil, gas, biomass as fuel.

This series of Rotary Single Cylinder Drying Machine have a variety of models, which can be selected according to the actual output, or customized.

The main technical parameters are shown in the following table:

|

Model |

Diameter (mm) |

Length (mm) |

Dimensions (mm) |

Speed (r/min) |

Motor

|

Power (kw) |

|

YZHG-0880 |

800 |

8000 |

9000×1700×2400 |

6 |

Y132S-4 |

5.5 |

|

YZHG-10100 |

1000 |

10000 |

11000×1600×2700 |

5 |

Y132M-4 |

7.5 |

|

YZHG-12120 |

1200 |

12000 |

13000×2900×3000 |

4.5 |

Y132M-4 |

7.5 |

|

YZHG-15150 |

1500 |

15000 |

16500×3400×3500 |

4.5 |

Y160L-4 |

15 |

|

YZHG-18180 |

1800 |

18000 |

19600×3300×4000 |

4.5 |

Y225M-6 |

30 |

|

YZHG-20200 |

2000 |

20000 |

21600×3650×4400 |

4.3 |

Y250M-6 |

37 |

|

YZHG-22220 |

2200 |

22000 |

23800×3800×4800 |

4 |

Y250M-6 |

37 |

|

YZHG-24240 |

2400 |

24000 |

26000×4000×5200 |

4 |

Y280S-6 |

45 |

Product detail pictures:

Related Product Guide:

Compound fertilizer production process

Complete production equipment for organic fertilizer

Batching method: automatic batching; Fast delivery China Counterflow Cooler - Rotary Single Cylinder Drying Machine in Fertilizer Processing – YiZheng , The product will supply to all over the world, such as: Angola, Bangkok, Namibia, Organic fertilizers can be divided into powder and granular organic fertilizers according to their forms. The production of granular organic fertilizers requires a granulator. Common organic fertilizer granulation equipment on the market: roller extrusion granulator, organic fertilizer stirring tooth granulator, drum granulator, disc granulator, compound fertilizer granulator, buffer granulator, Different granulators such as flat die extrusion granulator, twin screw extrusion granulator, etc.

We have been engaged in this industry for many years, we appreciate the work attitude and production capacity of the company, this is a reputable and professional manufacturer.