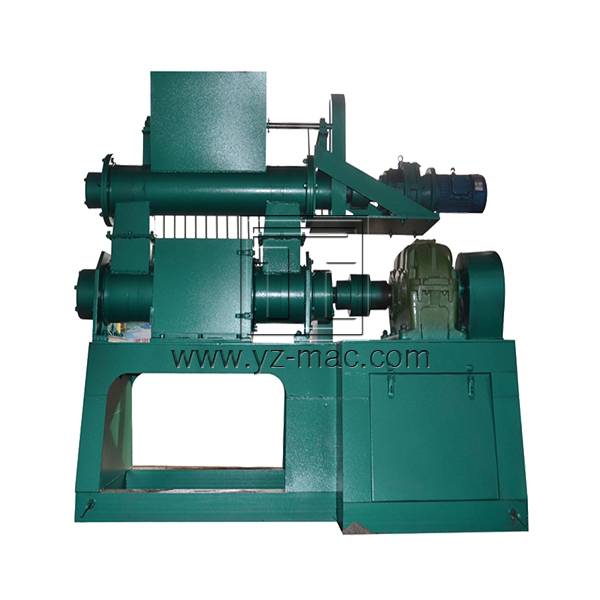

Factory wholesale Straw Particle Crusher - Two-Stage Fertilizer Crusher Machine – YiZheng

Factory wholesale Straw Particle Crusher - Two-Stage Fertilizer Crusher Machine – YiZheng Detail:

The Two-Stage Fertilizer Crusher Machine is a new type crusher that can easily crush high-humidity coal gangue, shale, cinder and other materials after long-term investigation and careful design by people from all walks of life. This machine is suitable for crushing raw materials such as coal gangue, shale, slag, slag, slag construction waste, etc. The crushing particle size is less than 3mm, and it is convenient to use gangue and cinder as additives and internal fuel for brick factories; it solves the production standard of gangue, shale, bricks, thermal insulation wall materials and other high-temperature materials which are difficult to crush.

The two sets of rotors connected in series make the material crushed by the upper-level rotor immediately be crushed again by the hammer head of the fast-rotating lower-level rotor. The materials in the inner cavity rapidly collide with each other and pulverize each other to achieve the effect of hammer powder and material powder. Finally, the material will be unloaded directly.

Production capacity: 1-10t/h

Feed granule size: ≤80mm

Suitable materials: Humic acid, cow dung, straw, sheep dung, chicken manure, sludge, biogas residue, coal gangue, slag etc.

1. Double rotor upper and lower two-stage crushing.

2. There is no screen, grate bottom, high humidity material, never clogging.

3. Double-rotor two-stage crushing, large output, discharge particle size below 3mm, less than 2mm accounting for more than 80%.

4. Wear-resistant combination hammer.

5. Unique shift adjustment technology.

6. Hydraulic electric starter housing.

|

Model |

YZFSSJ 600×400 |

YZFSSJ 600×600 |

YZFSSJ 800×600 |

YZFSSJ 1000×800 |

|

Feed size (mm) |

≤150 |

≤200 |

≤260 |

≤400 |

|

Discharge Size (mm) |

0.5-3 |

0.5-3 |

0.5-3 |

0.5-3 |

|

Capacity(t/h) |

2-3 |

2-4 |

4-6 |

6-8 |

|

Power(kw) |

15+11 |

18.5+15 |

22+18.5 |

30+30 |

Product detail pictures:

Related Product Guide:

Compound fertilizer production process

Complete production equipment for organic fertilizer

Compound fertilizer is a compound fertilizer that is mixed and batched according to different proportions of a single fertilizer, and a compound fertilizer containing two or more elements of nitrogen, phosphorus and potassium is synthesized through chemical reaction, and its nutrient content is uniform and the particle size is consistent. The raw materials for compound fertilizer production include urea, ammonium chloride, ammonium sulfate, liquid ammonia, monoammonium phosphate, diammonium phosphate, potassium chloride, potassium sulfate, including some fillers such as clay. In addition, organic materials such as various animal manures are added according to soil needs. Process flow of compound fertilizer production line: raw material batching→raw material mixing→granulation→drying→cooling→finished product screening→return particle crushing→coating→finished product packaging→storage. Factory wholesale Straw Particle Crusher - Two-Stage Fertilizer Crusher Machine – YiZheng , The product will supply to all over the world, such as: New Zealand, South Africa, Australia, Fertilizer crusher

The goods are very perfect and the company sales manager is warmful, we will come to this company to purchase next time.