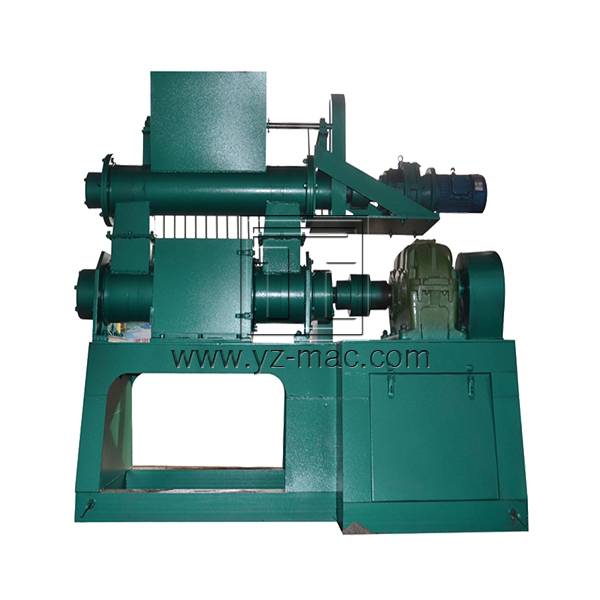

Factory wholesale Animal Manure Pellet Granulator - Double Screw Extruding Granulator – YiZheng

Factory wholesale Animal Manure Pellet Granulator - Double Screw Extruding Granulator – YiZheng Detail:

Double-Screw Extrusion granulation machine is a new granulation technology different from traditional granulation, which can be widely used in feed, fertilizer and other industries. Granulation is an important process especially for dry powder granulation. It not only determines the mass of granular fertilizer, but also relates to the quality and cost of fertilizer product.

This pelletizing function of Twin Screw Extrusion Fertilizer Granulator Machine is significantly enhanced by the special flowing mechanical condition and structure inside of the extruding zone. First of all, with the reverse rolling of the double screw, the materials in the extrusion area with repetitive high-speed strong rubbing and frequent shearing to increase the probability of mutual combining between the molecules of the materials. Second, the materials intense colliding and rubbing in extrusion area, make the extrusion pressure rising and keep stable in high pressure state. The temperature of extrusion area high pressure section can rise to above 75 ℃ rapidly. On the one hand, materials pressure and temperature are fully meet the granulating conditions. On the other hand, the strong homogeneous effect changed the molecular structure of materials, so that greatly improve the quality and strength of granules by the heat transferring and high-pressure extruding to get the higher quality fertilizer products.

(1) Reliable performance and high granulating rate, good granule strength and high bulk density

(2) Wide adaptability to raw materials.

(3) No destructive effect on material composition with low operating temperature.

(4) The granulation is finished by pressure, there’s no need any binder, it could promise the purity of product.

(5) The granulator has compact structure, easy for maintenance and repair

(6) Main driving parts are made of high quality alloy material, stainless steel, titanium, chromium etc., which are abrasion-proof, corrosion-proof, high temperature-proof, and have long service life.

|

Model |

Power |

Capacity |

Die Hole Diameter |

Overall Size (L × W × H) |

|

YZZLSJ-10 |

18.5kw |

1t/h |

Ф4.2 |

2185×1550×1900 |

|

YZZLSJ-20 |

30kw |

2t/h |

Ф4.2 |

2185×1550×1900 |

|

YZZLSJ-30 |

45kw |

3t/h |

Ф4.2 |

2555×1790×2000 |

|

YZZLSJ-40 |

55kw |

4t/h |

Ф4.2 |

2555×1790×2000 |

Product detail pictures:

Related Product Guide:

Compound fertilizer production process

Pig manure organic fertilizer complete equipment

The chain type turning mixer type large-scale composting equipment has the advantages of high efficiency, uniform mixing, thorough turning and long moving distance. The optional mobile car can realize the sharing of multi-tank equipment, and only need to build a fermentation tank to expand the production scale and improve the use value of the equipment. Factory wholesale Animal Manure Pellet Granulator - Double Screw Extruding Granulator – YiZheng , The product will supply to all over the world, such as: San Diego, Kyrgyzstan, Mexico, The fertilizer mixer can be customized according to the specific gravity of the material to be mixed, and the mixing capacity can be customized according to the actual needs of customers. The barrels are all made of high-quality stainless steel, which has strong corrosion resistance and is suitable for mixing and stirring of various raw materials.

The manufacturer gave us a big discount under the premise of ensuring the quality of products, thank you very much, we will select this company again.