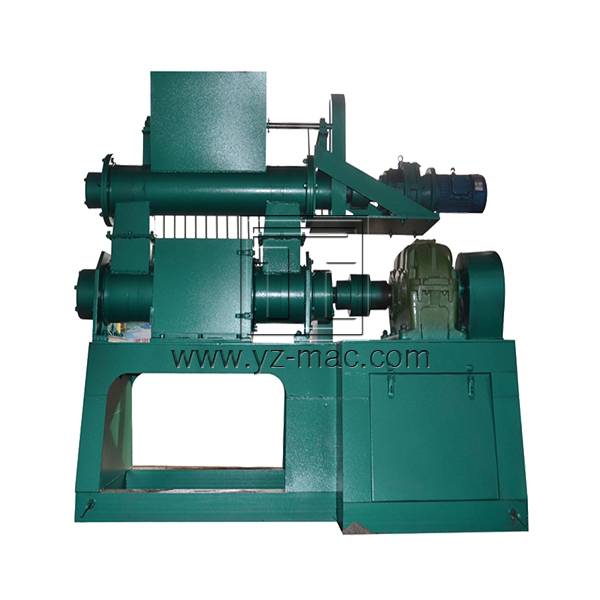

Factory Supply Vertical Crushing Machine - Fertilizer Urea Crusher Machine – YiZheng

Factory Supply Vertical Crushing Machine - Fertilizer Urea Crusher Machine – YiZheng Detail:

1. Fertilizer Urea Crusher Machine mainly uses the grinding and cutting of the gap between the roller and the concave plate.

2. The clearance size determines the degree of material crushing, and the drum speed and diameter can be adjustable.

3. When the urea enters the body, it hits the body wall and the baffle and is broken. Then it is ground into powder through the rack between the roller and the concave plate.

4. The clearance of the concave plate shall be adjustable to the extent of crushing by the regulating mechanism within 3-12 mm, and the feeding port regulator can control the production volume.

Before use, place the Fertilizer Urea Crusher Machine on a certain position in the workshop and connect it to the power source to use. The fineness of pulverization is controlled by the spacing of the two rollers. The smaller the spacing, the finer the fineness, and the relative reduction in output. The better the uniform pulverization effect is, the higher the output. The device can be designed to be mobile according to user requirements, and the user can move the corresponding position when using it, which is very convenient.

1. Especially for high moisture material, it has strong application and is not easy to block, and the material discharging is smooth.

2. Crushing blade adopts special material, and service life is triple times than other crusher machine.

3. It has high crushing efficiency; being equipped with observation window makes the wearing parts finish replacement in 10 minutes.

Q1: What is the Advantage of Urea Compound Fertilizer Crusher Machine?

A1: One year warranty, it has long service life on the operation of our manual brochure.

Q2: How to place order Urea Compound Fertilizer Crusher?

A2: You can directly order it online via Trade Assurance, we will receive your order and response you at once; After you confirm the suitable machine and deposit us via Trade Assurance, we will arrange the cargo timely.

Q3: Do you accept OEM special orders of Urea Compound Fertilizer Crusher ?

A3: OEM special order is also available because we have our own factory, which is a leading manufacturer in this field with 20 years of experience.

Q4: What is the real delivery time of your factory?

A4: 5 to 7 days for general series products, meanwhile, batches products & customized products would need 30 days to 60 days based on different conditions.

Q5: How do you ensure the quality of your Urea Compound Fertilizer Crusher ?

A5: Generally, our equipment are the most durable type our customers at home or abroad. With our experienced quality control team, we are trying to offer you the product with best quality. However, we do recognize that there do have small amount of the product which may got faulty or damaged for different reasons.

Q6: How does your after-sale service? got damaged?

A6: In the guarantee time 24 months, our general after-sale service is changing the damaged parts, but if the damage could be repaired by slight cost, we would wait for the customer’s bill for the fix cost and refund this part of cost. (Note: wear parts do not include.)

Welcome to your enquiry and visit to our factory!

|

Model |

Central Distance(mm) |

Capacity(t/h) |

Inlet Granularity(mm) |

Discharging Granularity(mm) |

Motor Power(kw) |

|

YZFSNF-400 |

400 |

1 |

<10 |

≤1mm (70%~90%) |

7.5 |

Product detail pictures:

Related Product Guide:

Complete production equipment for organic fertilizer

Compound fertilizer production process

During the fermentation process of the composter, it can maintain and ensure the alternating state of medium temperature - high temperature - medium temperature - high temperature, and effectively shorten the fermentation cycle Factory Supply Vertical Crushing Machine - Fertilizer Urea Crusher Machine – YiZheng , The product will supply to all over the world, such as: South Africa, Uzbekistan, Mombasa, New type organic fertilizer granulator

Customer service staff and sales man are very patience and they all good at English, product's arrival is also very timely, a good supplier.