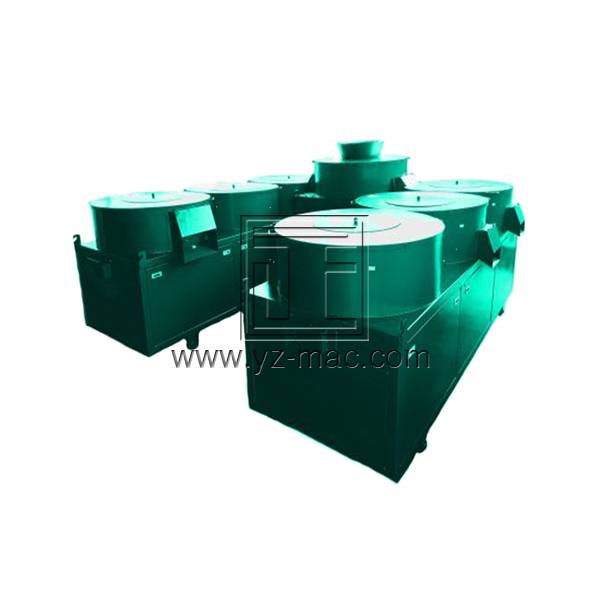

Factory Outlets Granulate Machine - Disc Organic & Compound Fertilizer Granulator – YiZheng

Factory Outlets Granulate Machine - Disc Organic & Compound Fertilizer Granulator – YiZheng Detail:

This series of granulating disc is equipped with three discharging mouth, facilitate continuous production, greatly reduces the labor intensity and improve labor efficiency. The reducer and motor use flexible belt drive to start smoothly, slow down the impact force and improve the service life of the equipment. The plate bottom is strengthened by a plurality of radiant steel plates, which is durable and never deformed. It is an ideal equipment for organic fertilizer and compound fertilizer, which is designed with thick, heavy and strong base, so it has no fixed anchor bolts and smooth operation.

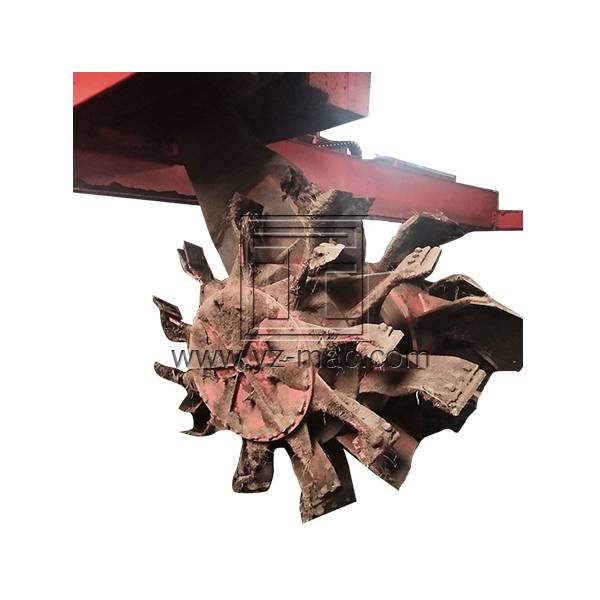

The degree of granulating pan can be adjusted from 35° to 50°. The pan rotates at a certain angle with the horizontal driven by the motor through reducer. The powder will rise along with the rotating pan under the friction between the powder and the pan; on the other hand, the powder will fall down under gravity. At the same time, the powder is pushed to the pan edge because of the centrifugal force. The powder materials roll in a certain trace under these three forces. It gradually becomes the required size, then overflow by the pan edge. It has the advantages of high granulating rate, uniform granule, high strength, easy operation, convenient maintenance, etc.

1.Raw material ingredients: Urea, ammonium nitrate, ammonium chloride, ammonium sulphate, ammonium phosphate (monoammonium phosphate, diammonium phosphate, and coarse whiting, ca), potassium chloride, potassium sulfate and other raw materials are matched in proportion (according to the market demand and the around soil of test results).

2.Raw materials mixing: The mixture of the ingredients should be mixed to improve the uniform fertilizer efficiency of the granules.

3.Granulation of raw material: The raw material after mixing equably will be sent to granulator (rotary drum granulator, or roll extrusion granulator both can be used here).

4.Granulation drying: put the granulation into the dryer, and the moisture in the granules will be dried, so that the granulation strength is increased and is easier to store.

5.Granulation cooling: After drying, the granulation’s temperature is too high and the granulation is easy to lump. While after cooling, it is easy to packing to save and transport.

6.Particle classification: the cooling particles that have been cooled will be graded: the unqualified particles will be crushed and re-granulated, and the qualified products will be sift out.

7.Finished film: The qualified products are coated to increase the brightness and roundness of granules.

8.Packaging of finished product: The particles that have been wrapped the film are stored in the ventilated place.

1. High efficiency. The circular granulation machine adopts the whole circular arc structure, the granulation rate can reach more than 95%.

2.The bottom of granulation plate is strengthened by a number of radiation steel plates, which are durable and never deformed.

3. Granulator plate lined with high strength glass steel, anti-corrosion and durable.

4. The raw materials have wide applicability. It can be used for the granulation of various raw material, like compound fertilizer, medicine, chemical industry, feed, coal, metallurgy.

5. Reliable operation and low cost. The machine’s power is small, and operation is reliable; there is no waste discharge during the whole granulating process, the operation is stable, and the maintenance is convenient.

|

Model |

Disc Diameter (mm) |

Edge height (mm) |

Volume (m³) |

Rotor Speed(r/min) |

Power (kw) |

Capacity (t/h) |

|

YZZLYP-25 |

2500 |

500 |

2.5 |

13.6 |

7.5 |

1-1.5 |

|

YZZLYP-28 |

2800 |

600 |

3.7 |

13.6 |

11 |

1-2.5 |

|

YZZLYP-30 |

3000 |

600 |

4.2 |

13.6 |

11 |

2-3 |

|

YZZLYP-32 |

3200 |

600 |

4.8 |

13.6 |

11 |

2-3.5 |

|

YZZLYP-45 |

4500 |

600 |

6.1 |

12.28 |

37 |

10 |

Product detail pictures:

Related Product Guide:

Complete production equipment for organic fertilizer

Compound fertilizer production process

The first stage is the exothermic stage, during which a lot of heat is generated. Factory Outlets Granulate Machine - Disc Organic & Compound Fertilizer Granulator – YiZheng , The product will supply to all over the world, such as: Orlando, Benin, Naples, Manure pellet machine

The customer service reprersentative explained very detailed, service attitude is very good, reply is very timely and comprehensive, a happy communication! We hope to have a opportunity to cooperate.