Disc granulator production equipment

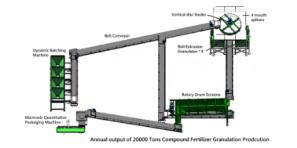

Disc granulator production equipment is a type of equipment used for granulating various materials into granules. The basic equipment that may be included in this set are:

1.Feeding Equipment: This equipment is used to deliver the raw materials into the disc granulator. It can include a conveyor or a feeding hopper.

2.Disc Granulator: This is the core equipment of the production line. The disc granulator consists of a rotating disc, a scraper, and a spraying device. The raw materials are fed into the disc, which rotates to form the granules. The scraper helps to move the materials around the disc, while the spraying device adds moisture to the materials to help them stick together.

3.Drying Equipment: This equipment is used to dry the organic fertilizer granules to a moisture content suitable for storage and transportation. Drying equipment can include a rotary dryer or a fluid bed dryer.

4.Cooling Equipment: This equipment is used to cool the dried organic fertilizer granules and make them ready for packaging. Cooling equipment can include a rotary cooler or a counterflow cooler.

5.Screening Equipment: This equipment is used to screen and grade the organic fertilizer granules according to particle size. Screening equipment can include a vibrating screen or a rotary screener.

6.Coating Equipment: This equipment is used to coat the organic fertilizer granules with a thin layer of protective material, which can help to prevent moisture loss and improve nutrient absorption. Coating equipment can include a rotary coating machine or a drum coating machine.

7.Packing Equipment: This equipment is used to pack the organic fertilizer granules into bags or other containers. Packing equipment can include a bagging machine or a bulk packing machine.

8.Conveyor System: This equipment is used to transport the organic fertilizer materials and finished products between different processing equipment.

9.Control System: This equipment is used to control the operation of the entire production process and ensure the quality of the organic fertilizer products.

It is important to note that the specific equipment needed may vary depending on the type of organic fertilizer being produced, as well as the specific requirements of the production process. Additionally, automation and customization of the equipment may also impact the final list of required equipment.