Countercurrent cooling equipment

Countercurrent cooling equipment is a type of cooling system commonly used in the production of fertilizer pellets. It works by using a series of pipes or a conveyor belt to transfer hot pellets from a dryer to a cooler. As the pellets move through the cooler, cool air is blown in the opposite direction, providing a countercurrent flow. This allows for more efficient cooling and prevents the pellets from overheating or breaking down.

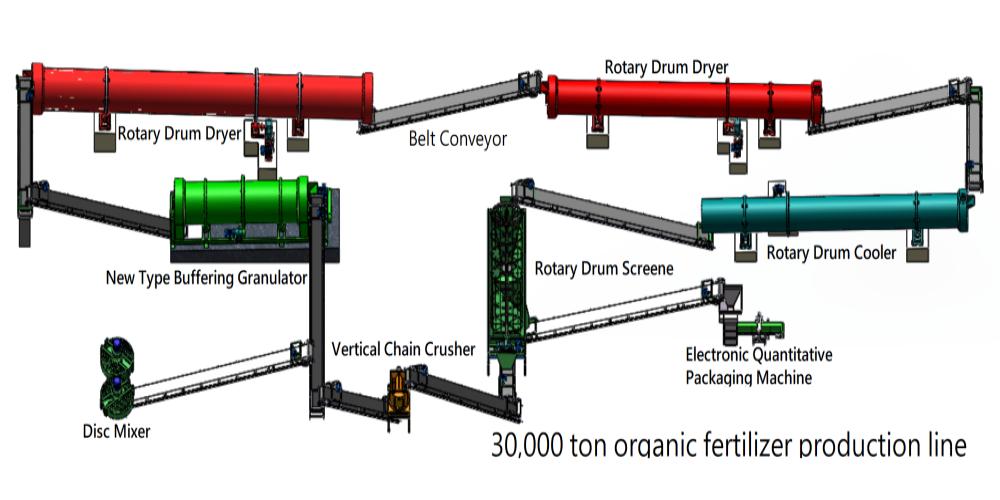

Countercurrent cooling equipment is typically used in conjunction with rotary drum dryers and rotary drum coolers, which are also common pieces of equipment used in the production of fertilizer pellets. The use of countercurrent cooling equipment can help to increase the efficiency of the cooling process, resulting in a higher-quality final product.