Compound fertilizer production equipment

Compound fertilizer production equipment is used to process raw materials into compound fertilizers, which are made up of two or more nutrient components, typically nitrogen, phosphorus, and potassium. The equipment is used to mix and granulate the raw materials, creating a fertilizer that provides balanced and consistent nutrient levels for crops.

Some common types of compound fertilizer production equipment include:

1.Crushing equipment: Used to crush and grind raw materials into small particles, making it easier to mix and granulate.

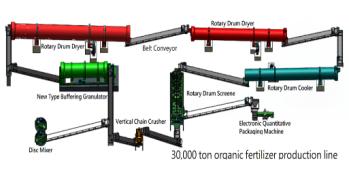

2.Mixing equipment: Used to blend the different raw materials together, creating a homogeneous mixture. This includes horizontal mixers, vertical mixers, and disc mixers.

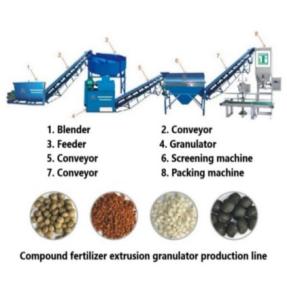

3.Granulating equipment: Used to convert the mixed materials into granules or pellets, which are easier to store, transport and apply. This includes rotary drum granulators, double roller granulators, and pan granulators.

4.Drying equipment: Used to remove the moisture from the granules, making them easier to handle and store. This includes rotary dryers and fluidized bed dryers.

5.Cooling equipment: Used to cool the granules after drying, preventing them from sticking together or breaking down. This includes rotary coolers and counter-flow coolers.

6.Screening equipment: Used to remove any oversized or undersized granules, ensuring that the final product is of consistent size and quality.

7.Packaging equipment: Used to package the final product into bags or containers for storage and distribution.

Compound fertilizer production equipment can be customized to suit different production capacities and requirements, depending on the specific needs of the user. The equipment is designed to produce high-quality, balanced fertilizers that provide consistent nutrient levels for crops.