Compost fertilizer machine

A compost fertilizer machine is specialized equipment designed to efficiently produce high-quality organic fertilizer from composted organic materials. These machines automate and streamline the process of converting compost into a nutrient-rich fertilizer that can be used in agricultural, horticultural, and gardening applications.

Material Pulverization:

Compost fertilizer machines often include a material pulverization component. This component is responsible for breaking down the composted organic materials into fine particles. It helps increase the surface area of the compost, facilitating the subsequent stages of the fertilizer production process.

Mixing and Blending:

After pulverization, the composted materials are mixed and blended with other additives or ingredients. This step ensures the incorporation of essential nutrients, such as nitrogen, phosphorus, and potassium, into the final fertilizer product. Mixing and blending components in the machine ensure the homogeneous distribution of nutrients throughout the fertilizer mixture.

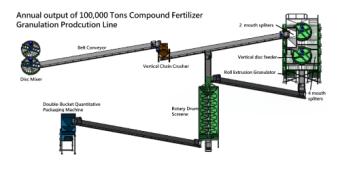

Granulation:

Granulation is a crucial step in the compost fertilizer production process. Compost fertilizer machines are equipped with granulation components that convert the mixture into granules of uniform size and shape. Granulation improves the handling, storage, and application properties of the fertilizer, making it easier to distribute and use effectively.

Drying:

The moisture content of the granulated fertilizer is reduced through the drying process. Compost fertilizer machines typically include drying components that utilize heat sources or airflow systems to remove excess moisture. Drying ensures the stability and preservation of the fertilizer, preventing clumping and extending its shelf life.

Cooling:

After drying, the granulated fertilizer is cooled to room temperature. Cooling components in the compost fertilizer machine facilitate rapid cooling to prevent further moisture absorption and maintain the integrity of the granules. This step ensures that the fertilizer is ready for packaging and subsequent storage or distribution.

Screening and Grading:

To ensure the quality and uniformity of the final product, compost fertilizer machines incorporate screening and grading components. These components separate oversized or undersized granules, as well as any foreign matter, to achieve a consistent particle size distribution. Screening and grading enhance the marketability and effectiveness of the fertilizer.

Packaging and Sealing:

The final stage of the compost fertilizer production process involves packaging and sealing the granulated fertilizer. Compost fertilizer machines are equipped with packaging components that efficiently fill bags or containers with the desired amount of fertilizer. Some machines also include sealing mechanisms to ensure the integrity and freshness of the packaged fertilizer.

Automation and Control:

Compost fertilizer machines are designed with automation and control systems to streamline the production process. These systems monitor and regulate various parameters, such as mixing ratios, granulation speed, drying temperature, and cooling time. Automation and control enhance the efficiency, accuracy, and consistency of the fertilizer production process.

By utilizing a compost fertilizer machine, businesses can transform composted organic materials into high-quality organic fertilizer. This fertilizer provides essential nutrients to plants, improves soil fertility, promotes sustainable agriculture, and reduces dependence on chemical fertilizers. A compost fertilizer machine offers efficiency, automation, and precise control, contributing to the production of nutrient-rich organic fertilizers that support healthy crop growth and environmental sustainability.