Complete production equipment for chicken manure fertilizer

The complete production equipment for chicken manure fertilizer typically includes the following machines and equipment:

1.Solid-liquid separator: Used to separate the solid chicken manure from the liquid portion, which makes it easier to handle and transport. This includes screw press separators, belt press separators, and centrifugal separators.

2.Composting equipment: Used to compost the solid chicken manure, which helps to break down the organic matter and convert it into a more stable, nutrient-rich fertilizer. This includes windrow turners, groove type compost turners, and chain plate compost turners.

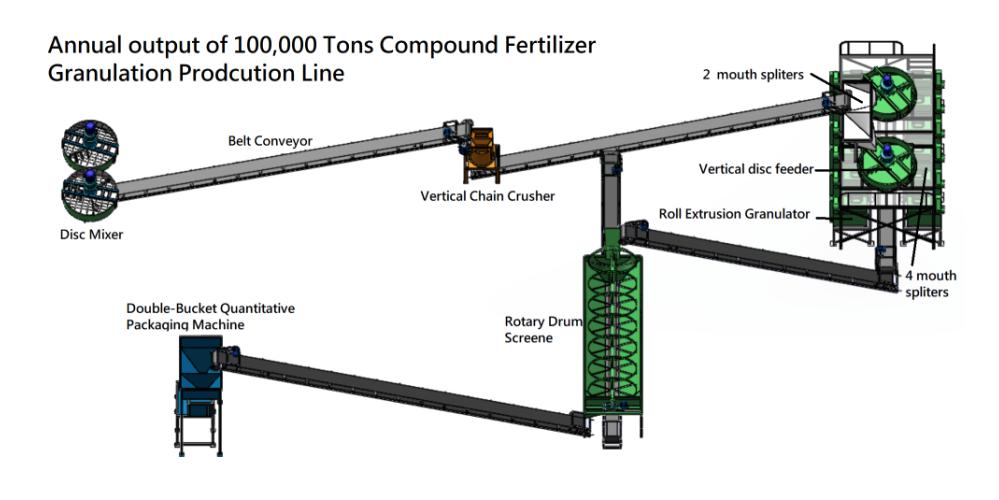

3.Crushing and mixing equipment: Used to crush and mix the composted material with other additives, such as minerals and microorganisms, to create a balanced fertilizer blend. This includes crushers, mixers, and shredders.

4.Granulating equipment: Used to convert the mixed material into granules or pellets. This includes pan granulators, rotary drum granulators, and disc granulators.

5.Drying equipment: Used to reduce the moisture content of the granules, making them easier to handle and store. This includes rotary dryers, fluidized bed dryers, and belt dryers.

6.Cooling equipment: Used to cool the granules after drying to prevent them from sticking together or breaking down. This includes rotary coolers, fluidized bed coolers, and counter-flow coolers.

7.Screening equipment: Used to remove any oversized or undersized granules from the final product, ensuring that the product is of consistent size and quality. This includes vibrating screens and rotary screens.

8.Packing equipment: Used to package the final product into bags or containers for storage and distribution. This includes automatic bagging machines, filling machines, and palletizers.

The complete production equipment for chicken manure fertilizer can be customized to suit different production capacities and requirements, depending on the specific needs of the user. The equipment is designed to produce high-quality, organic fertilizers that provide a balanced blend of nutrients for plants, helping to increase yields and improve soil health.