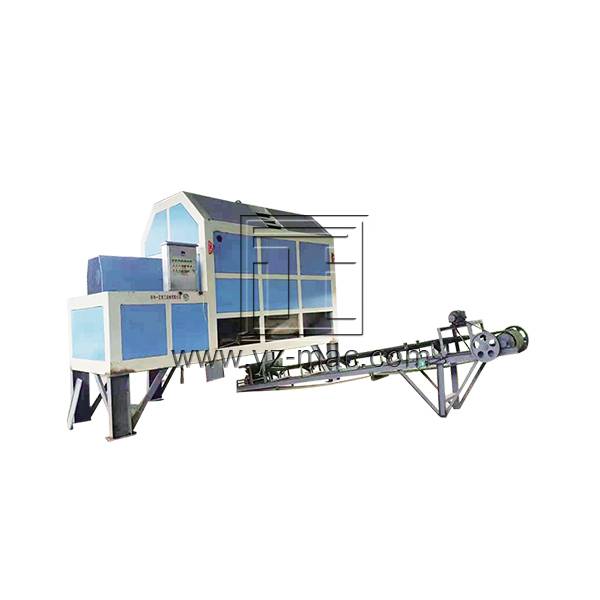

Chinese wholesale Fermentation Compost Equipment - Self-propelled Composting Turner Machine – YiZheng

Chinese wholesale Fermentation Compost Equipment - Self-propelled Composting Turner Machine – YiZheng Detail:

The Self-propelled Groove Composting Turner Machine is the earliest fermentation equipment, it is widely used in organic fertilizer plant, compound fertilizer plant, sludge and garbage plant, horticultural farm and bisporus plant for fermentation and the removal of water. The spans can be 3-30 meters and the height can be 0.8-1.8 meters. We have double-groove type and half-groove type to meet the customers’ different needs.

➽1. Agricultural waste: straw, dregs of beans, cotton dregs, rice bran, etc.

➽2. Animal manure: mixture of poultry litter and animal waste, such as the wastes of slaughterhouse, fish market, urine and dung of cattle, pigs, sheep, chicken, ducks, geese, goat, etc.

➽3. Industrial waste: wine lees, vinegar residue, manioc waste, sugar scum, furfural residue, etc.

➽4. Home scrap: food waste, the roots and leaves of vegetables, etc.

➽5. Sludge: the sludge of the river, sewer, etc.

(1)High efficiency, smooth operation, durable, and even composting;

(2)It can be controlled by cabinet manually or automatically;

(3)With the soft start to prolong the service life;

(4)The Self-propelled Groove Composting Turner Machine is optional equipped with hydraulic lifting system;

(5)Durable pulling teeth can break and mix the material;

(6)Travel limiting switch ensure safety of the rolling.

Compared with the traditional turning equipment, the forklift type compost making machine integrates the crushing function after fermentation.

(1) It has the advantages of high crushing efficiency and uniform mixing;

(2) The turning is thorough and time-saving;

(3) It’s adaptable and flexible, and not limited by environment or distance.

|

Model |

YZFDXZ-2500 |

YZFDXZ-3000 |

YZFDXZ-4000 |

YZFDXZ-5000 |

|

Turning Width(mm) |

2500 |

3000 |

4000 |

5000 |

|

Turning Depth(mm) |

800 |

800 |

800 |

800 |

|

Main Motor (kw) |

15 |

18.5 |

15*2 |

18.5*2 |

|

Moving Motor(kw) |

1.5 |

1.5 |

1.5 |

1.5 |

|

Lifting Motor(kw) |

0.75 |

0.75 |

0.75 |

0.75 |

|

Working Speed (m/min) |

1-2 |

1-2 |

1-2 |

1-2 |

|

Weight(t) |

1.5 |

1.9 |

2.1 |

4.6 |

Product detail pictures:

Related Product Guide:

Compound fertilizer production process

Complete production equipment for organic fertilizer

Pig manure cow manure turning machine farm composting fermentation roulette turning machine small organic fertilizer supporting equipment, small chicken manure pig manure, fermentation manure turning machine, organic fertilizer turning machine for sale Chinese wholesale Fermentation Compost Equipment - Self-propelled Composting Turner Machine – YiZheng , The product will supply to all over the world, such as: Spain, Berlin, Romania, Organic fertilizer mixer machine

The goods are very perfect and the company sales manager is warmful, we will come to this company to purchase next time.