Bottom price Rotary Drum Slag Dryer - Pulverized Coal Burner – YiZheng

Bottom price Rotary Drum Slag Dryer - Pulverized Coal Burner – YiZheng Detail:

The Pulverized Coal Burner is suitable for heating various annealing furnaces, hot blast furnaces, rotary furnaces, precision casting shell furnaces, smelting furnaces, casting furnaces and other related heating furnaces. It is an ideal product for energy saving and environmental protection, it is well received by customers.

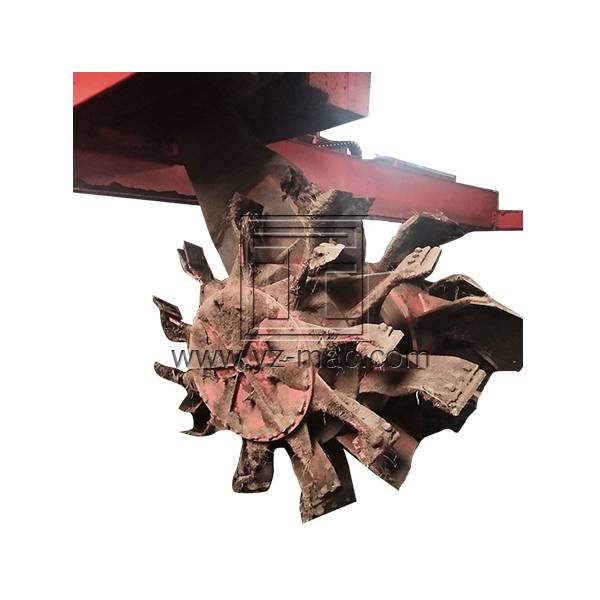

1. Adopts new structure, change the traditional burner mechanism, exclusive use of rotary combustion burners to solve the traditional burn which is easy to slag-bonding, cannot burn completely etc.

2. High flame temperature, energy saving and completely burning.

3. Adopts the exclusive ingredients of firebrick of high performance, prolong service life

4. Production cost is low, is only the 1/3 of oil burner.

5. With high automaticity, convenient to control aggregate temperature, discharging aggregate through dry mixing drum.

7. Port temperature measuring equipment return signal to the frequency changer of coal machine, change the aggregate temperature through frequency changer automatically control the volume of coal.

The Pulverized Coal Burner has a specially designed multi-stage and multi-nozzle air supply guide structure, which can generate high-temperature air in a short time, with safe combustion, high heat utilization, smoke and dust removal, high efficiency, energy saving and other advantages:

(1) The residence time of pulverized coal in the high temperature zone of Pulverized Coal Burner is long, so the combustion efficiency is high, and the flue is directly filled with no black smoke, but steamy white smoke

(2) This type of Pulverized Coal Burner has a shorter temperature rise time during heating, high thermal efficiency, low coal quality requirements, wide application of coal types, and high economic benefits

(3) The Pulverized Coal Burner is easy to ignite, heats up quickly, and the work efficiency is obviously improved

(4) The internal air supply and coal input of the Pulverized Coal Burner can be changed as required, and the furnace temperature and flame length can be adjusted in a short time to meet actual needs.

(5) The internal temperature of the Pulverized Coal Burner is uniform, the heating space is large, the slag does not stick to the surface.

|

Model (Coal consumption) |

Outer diameter(mm) |

Inner diameter(mm) |

Remark |

|

YZMFR-S1000kg |

780 |

618 |

Stainless Steel |

|

YZMFR-1000kg |

1040 |

800 |

Firebrick |

|

YZMFR-S2000kg |

900 |

700 |

Stainless Steel |

|

YZMFR-2000kg |

1376 |

1136 |

Firebrick |

|

YZMFR-S3000kg |

1000 |

790 |

Stainless Steel |

|

YZMFR-3000kg |

1500 |

1250 |

Firebrick |

|

YZMFR-S4000kg |

1080 |

870 |

Stainless Steel |

|

YZMFR-4000kg |

1550 |

1300 |

Firebrick |

Product detail pictures:

Related Product Guide:

Complete production equipment for organic fertilizer

Compound fertilizer production process

The composting machine realizes the complete fermentation and composting of fertilizers, and can realize the turning and fermentation of high stacking, which improves the speed of aerobic fermentation. Our company produces chain plate type pile turner, walking type pile turner, double screw pile turner, trough type tiller, trough type hydraulic pile turner, crawler type pile turner, horizontal fermentation tank, roulette pile turner Customers can choose different composting machines such as composting machines, forklift composting machines, etc. according to the actual composting raw materials, sites and products. Bottom price Rotary Drum Slag Dryer - Pulverized Coal Burner – YiZheng , The product will supply to all over the world, such as: Dominica, Tunisia, Barcelona, The double-stage pulverizer is widely used in municipal solid waste, distiller's grains, mushroom residue, etc. The preferred compost pulverizer has upper and lower poles for pulverizing, and two sets of rotors connected in series with each other. The pulverized materials are pulverized by each other to achieve the pulverizing effect.

With a positive attitude of "regard the market, regard the custom, regard the science", the company works actively to do research and development. Hope we have a future business relationships and achieving mutual success.