Best quality Compost Windrow Turner - Hydraulic Lifting Composting Turner – YiZheng

Best quality Compost Windrow Turner - Hydraulic Lifting Composting Turner – YiZheng Detail:

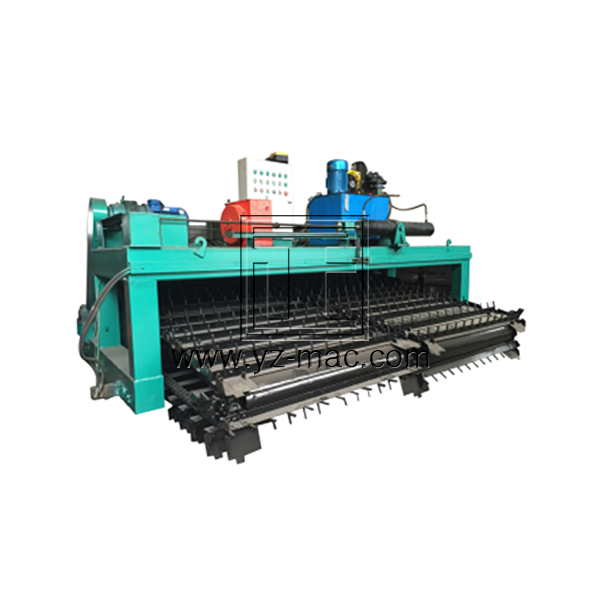

The Hydraulic Organic Waste Composting Turner Machine absorbs the advantages of advanced production technology at home and abroad. It makes full use of the research results of high-tech biotechnology. The equipment integrates mechanical, electrical and hydraulic integrated control technology. While ventilating and oxygenating the composting materials, it can also accurately control the temperature and humidity of the composting materials so as to make the composting materials rapidly mature, which can basically meet the requirements of large-scale composting production of organic fertilizer.

1) Suitable for the turning and fermentation of organic waste, such as, sludge waste, sugar mill filter mud, bad slag cake and straw sawdust.

2) Widely used in the fermentation composting and removal of moisture operations of organic fertilizer, fertilizer, sludge dumps, horticulture course and Mushroom cultivation factory.

3) It can be used with solar fermentation, fermentation tank and mobile machine, etc. And mobile machine can realize more slot machine used in function.

4) Fermented and its supporting material can also be a continuous bulk discharge.

5) efficiency, smooth operation, strong and durable, even turning throw.

6) Centralized control cabinet, can achieve the manual or automatic control function

7) Equipped with soft starter, start-up impact load is low

8) Equipped with a stir tooth hydraulic lifting system.

9) Limit travel switch, play the role of safe and limit.

The main shaft of the Hydraulic Lifting Composting Turner adopts a long knife bar with a left and right spiral and a small shaft diameter, so that the machine can evenly turn the material, has good gas permeability, high breaking rate and low resistance. The transmission part adopts a large pitch chain drive, which makes the power efficiency high, the noise is low, the operation is stable, and the slip is not slippery. The shape is fully sealed, safe and reliable. The appliance is fully controlled with one box, making it easy and safe to operate.

|

Model |

Length (mm) |

Power (kw) |

Walk Speed (m/min) |

Capacity (m³/h) |

|

YZFJYY-3000 |

3000 |

15+15+0.75 |

1 |

150 |

|

YZFJYY-4000 |

4000 |

18.5+18.5+0.75 |

1 |

200 |

|

YZFJYY-5000 |

5000 |

22+22+2.2 |

1 |

300 |

|

YZFJYY-6000 |

6000 |

30+30+3 |

1 |

450 |

Product detail pictures:

Related Product Guide:

Complete production equipment for organic fertilizer

Compound fertilizer production process

Condition control of organic fertilizer production is the interaction of physical and biological characteristics in the composting process, and the control conditions are the coordination of the interaction. Best quality Compost Windrow Turner - Hydraulic Lifting Composting Turner – YiZheng , The product will supply to all over the world, such as: Portland, Florida, Philadelphia, The fertilizer granulator is the core part of the organic fertilizer production line, and the granulator is used to manufacture dust-free granules with controllable size and shape. The granulator achieves high-quality and uniform granulation through the continuous process of stirring, collision, inlay, spheroidization, granulation, and densification.

With a positive attitude of "regard the market, regard the custom, regard the science", the company works actively to do research and development. Hope we have a future business relationships and achieving mutual success.